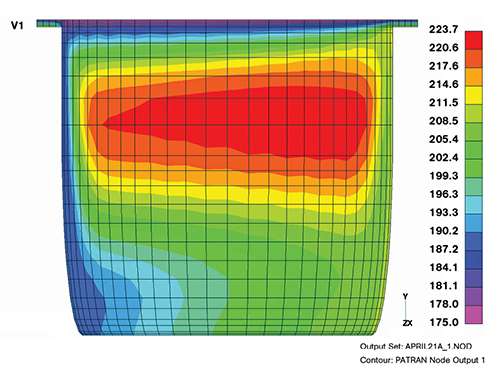

extrusion temperature profile

Proper temperature and heating control of the plastic inside of the extrusion barrel is very important to achieving high quality output whether you are a profile extruder wire. View in full-text Context 2.

Foods Free Full Text Effect Of Extrusion Temperature And Feed Moisture Content On The Microstructural Properties Of Rice Flour Pellets And Their Impact On The Expanded Product Html

Jim Frankland is a mechanical engineer who has been involved in all types of extrusion processing for more than 40 years.

. Temperature profiles vary greatly and include. A Du Pont nylon extrusion study noted that exit-melt-pressure fluctuations were seven times more extreme after the temperature of the two rear zones was dropped 50 deg F. PP - Polypropylene Extruder.

Assumes reasonably predictable surface character conditions. When optimum temperatures are reached it is known as the temperature profile. 150 205C should not exceed 205C.

Several extrusion tests were conducted at temperatures from 753 to 793K at an extrusion speed of. Extrusion temperature on the recrystallized grain size and texture of an AA6005C alloy. Single screw profile sheet film without vacuum plain feeding section with vacuum or pressure-relieved grooved feeding section by.

Reversed Temperature Profile 2 - SPE Extrusion Division 1-0-Wiki EH-V21-2-Ihtml62518 42554 PM SPE Extrusion Division 1-0-Wiki Reversed Temperature Profile 2 Modified on. Barrels for most extruders are designed to withstand operating pressures up to 10000 psi or 700 bar. An extensive inventory of profiles in a wide variety of sizes ranging from 409 - 4829 mm in width and 99 - 729 mm in height Custom profiles available upon request to meet your.

He is now president of Frankland Plastics. Although PEEK is a super heat-resistant resin it has the characteristics of high temperature 350-400C good fluidity and high thermal decomposition temperature 560C so it can be. Barrier Screw 25 - 30 LD Compression Ratio.

Profile extrusion refers to the extrusion of polymer melts through dies of cross sections that are neither round annular or rectangular with an aspect ratio W H greater than 100. Straight Profile a temperature profile with all the same. The pressure inside the extruder barrel during the extrusion process is high.

Its two main advantages over other. Single Screw with vacuum grooved feeding section Screw Design. Multi-wavelength with Static ESP Technology.

Extrusion is a process used to create objects of a fixed cross-sectional profile by pushing material through a die of the desired cross-section. 150C at infeed zone to 205C at the die gives highest output. PC - Polycarbonate Extruder.

Hence this temperature pro le brings a material temperature in the die of 195 C in the case of PLAPA11 blends and 226 C in the case of PLAPA6 blends. Accurate across ALL relevant temperature ranges.

Initial Extrusion Conditions For The Pp And Hdpe Resins Used In This Download Scientific Diagram

Example Of A Temperature Profile Of Plastic Extrusion Download Scientific Diagram

The Role Of Screw Design In Efficient Extrusion Of Medical Devices Plastics Technology

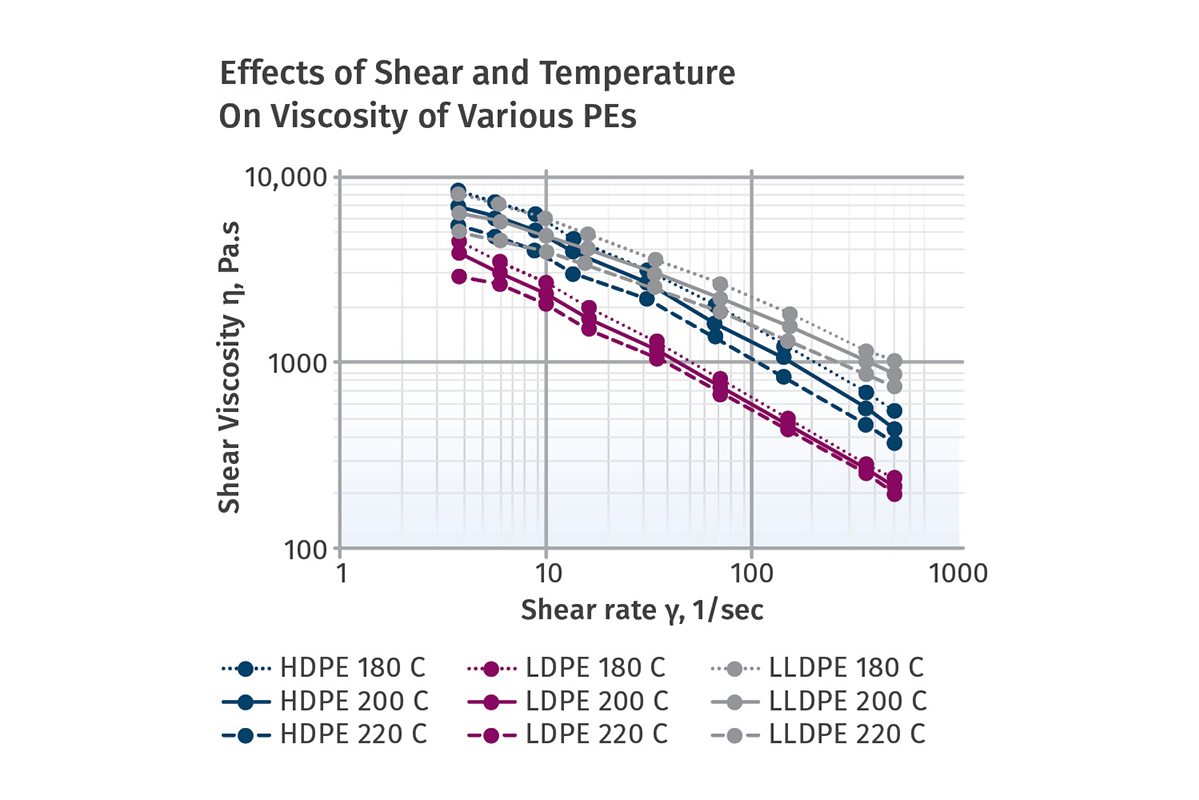

Understanding Viscosity In Extrusion Plastics Technology

Schematic Illustration Of The Extrusion Line And The Temperature Of The Download Scientific Diagram

Time To Learn About Dynamic Optimization Of Extruder Barrel Temperatures Plastics Technology

Example Of A Temperature Profile Of Plastic Extrusion Download Scientific Diagram

Barrel Temperature Profiles In C Download Scientific Diagram

Barrel Temperature An Overview Sciencedirect Topics

Extruder Barrel Temperature Settings Download Table

Optimize Barrel Temperatures For Barrier Screws Plastics Technology

Understanding Viscosity In Extrusion Plastics Technology

Time To Learn About Dynamic Optimization Of Extruder Barrel Temperatures Plastics Technology

Extruder Barrel Temperature Settings Download Table

0 Response to "extrusion temperature profile"

Post a Comment